Optional Accessory Offers Precision Control for Crucible Handling, Maintenance on Larger Growers

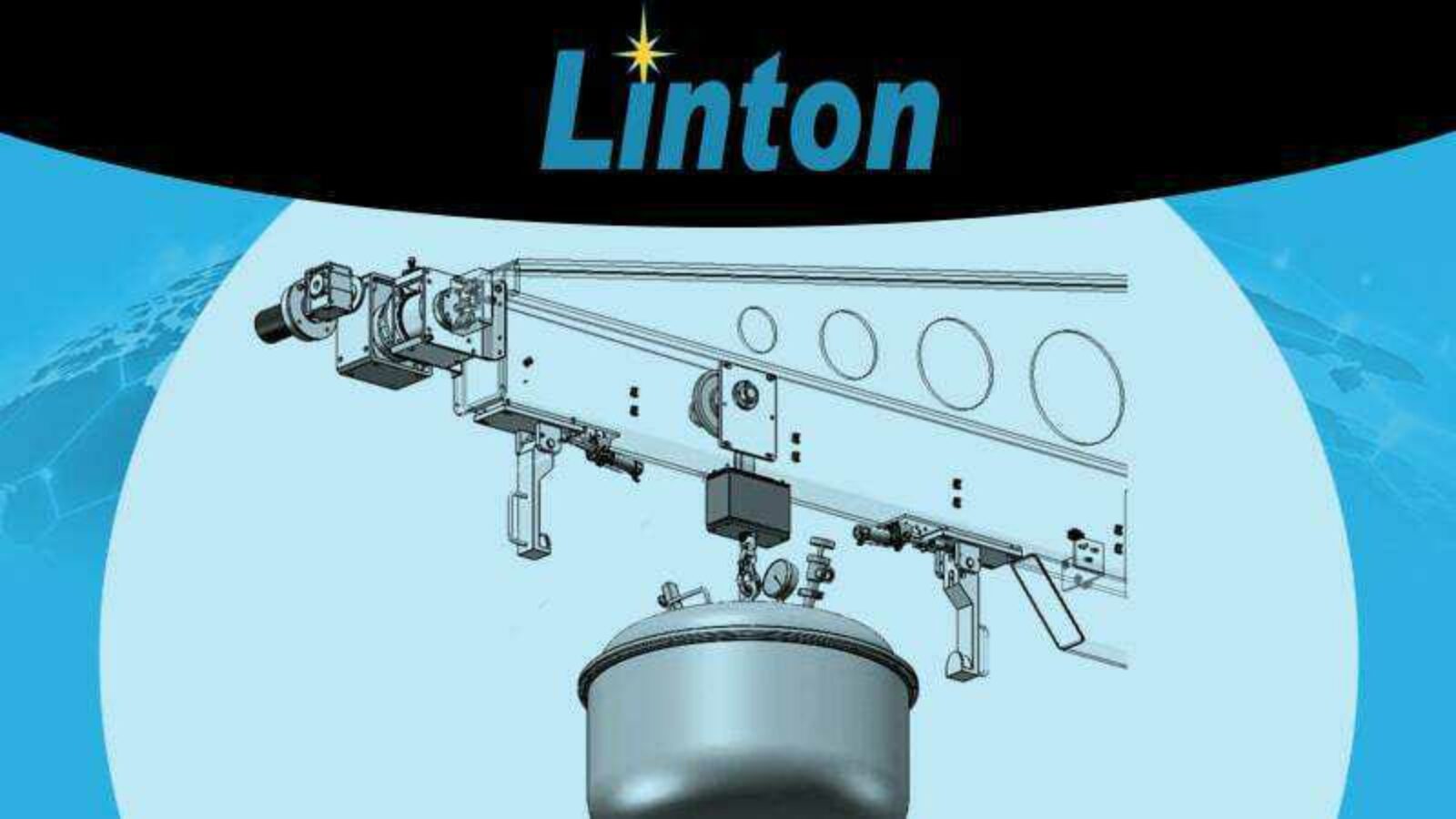

Linton Crystal Technologies has introduced a new accessory for its Czochralski (CZ) process crystal growers that offers precise control of crucible handling and other maintenance functions. The patent-pending Crucible Handling System (CHS), a crystal growing assembly with combination lift arm and winch, can be included with any of Linton’s growers. However, it was particularly designed to overcome challenges of loading and unloading crucibles on larger machines such as the KX240 up to the KX360.

“Our original crucible handling system was designed to handle crucibles charged for 20- to 22-inch hot zones. We found this system was not effective for crucibles 24-inches and larger,” explains John Reese, mechanical engineering manager for Linton. “The larger loads require counterbalances to keep the cart from tipping. With the trend toward larger machines with larger hot zones, we saw the opportunity to rethink the whole crucible handling process to offer a better solution overall.”

The original system relies on a mechanized cart with walk-behind controls and a crane arm. It is maneuvered in place next to the grower and centered, then the crane arm is swung into place to raise or lower the crucible. “The process of centering is time consuming and usually done where there is limited space. There is always the risk that the operator could bump the cart into the grower in the process, possibly taking the machine off level,” says Reese.

The new Crucible Handling System works with current 28,” 32,” and 36” hot zones and also will be able to work with future crucible sizes. It is attached to and centered on the grower. It lifts the pre-charged crucible from the factory floor and then precisely locates the crucible over the open furnace tank before gently lowering and positioning it into the hot zone. A vacuum head is used to securely grab and hold the crucible bowl throughout the process.

“In addition to providing more precise control and safety in crucible handling, the integrated arm acts as the grower’s own service crane,” adds Reese.

The winch system provides a clean, convenient and safe means of maintaining the inner workings of the furnace. For example, it can be used to position hot zone components like the heater and the gas shield or maintaining the crucible shaft.

Linton is the world leader in the design, development and manufacture of equipment for producing monocrystalline ingots for the solar, semiconductor and specialty materials industries. The company specializes in silicon and produces equipment for materials such as germanium and gallium arsenide. They also provide technical support, process engineering support and replacement parts to help clients get businesses off the ground, improve productivity and continue to innovate.