CZ Growing Equipment

Producing the highest quality silicon ingots at some of the industry’s fastest speeds, lowest costs and largest formats.

Our family of Czochralski (CZ) furnaces is designed to produce the highest quality silicon ingots at some of the industry’s fastest speeds, lowest costs and largest formats. We customize every product for every customer, whether it’s the modification of one part, or a complete, state-of-the-art crystal growing system tailored precisely to your needs.

Linton is a leader in CZ growing equipment for ingots used in machined silicon parts, optics, sputtering targets, etch electrodes and more. Over the years, our CZ furnaces have created ingots that provide electrical power for satellites, heat-resistant mirrors for our national defense systems and the machined parts that produce next-generation integrated circuits and solar cells.

Our product line by industry.

Options & Accessories

Let us help you assemble a complete Czochralski (CZ) furnace system for optimal performance.

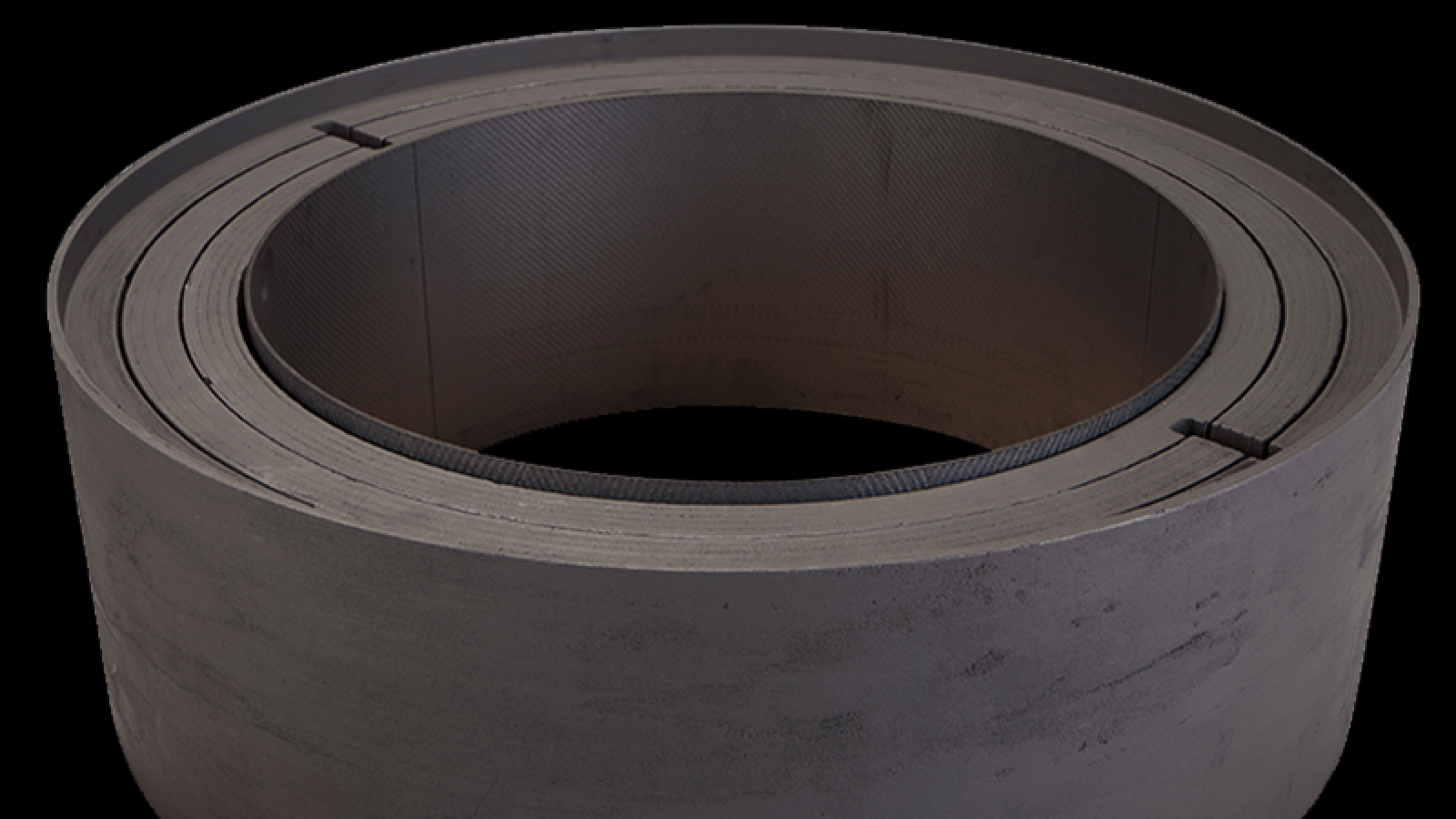

Hotzones

Low-Power Consumption

Cooling Tubes

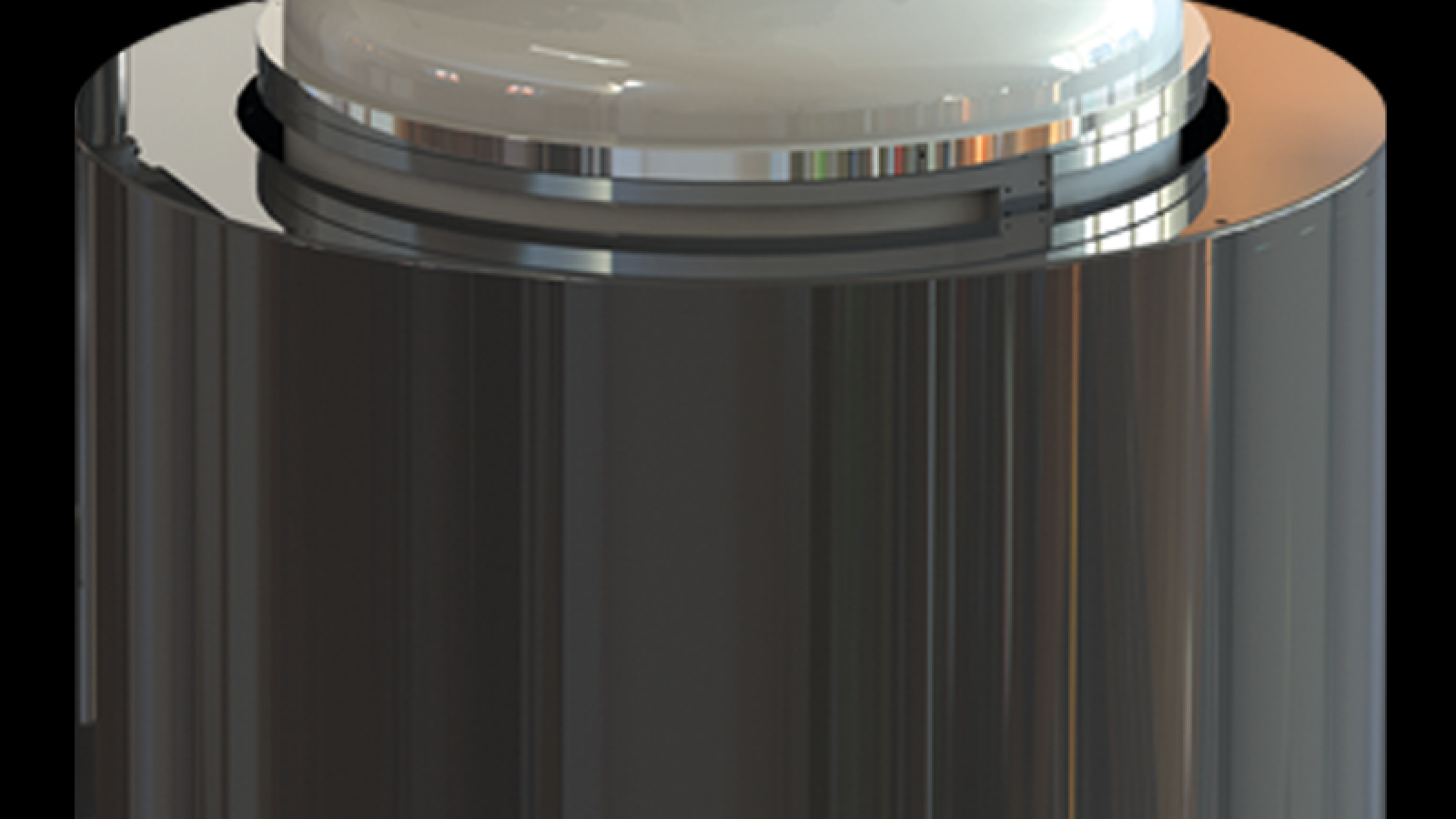

Magnets

Resistive Magnets

Superconducting Magnets

Vacuum Pumps

Main Vacuum Pumps

Auxiliary Vacuum Pumps

Feeding

Internal Feeders

External Feeders

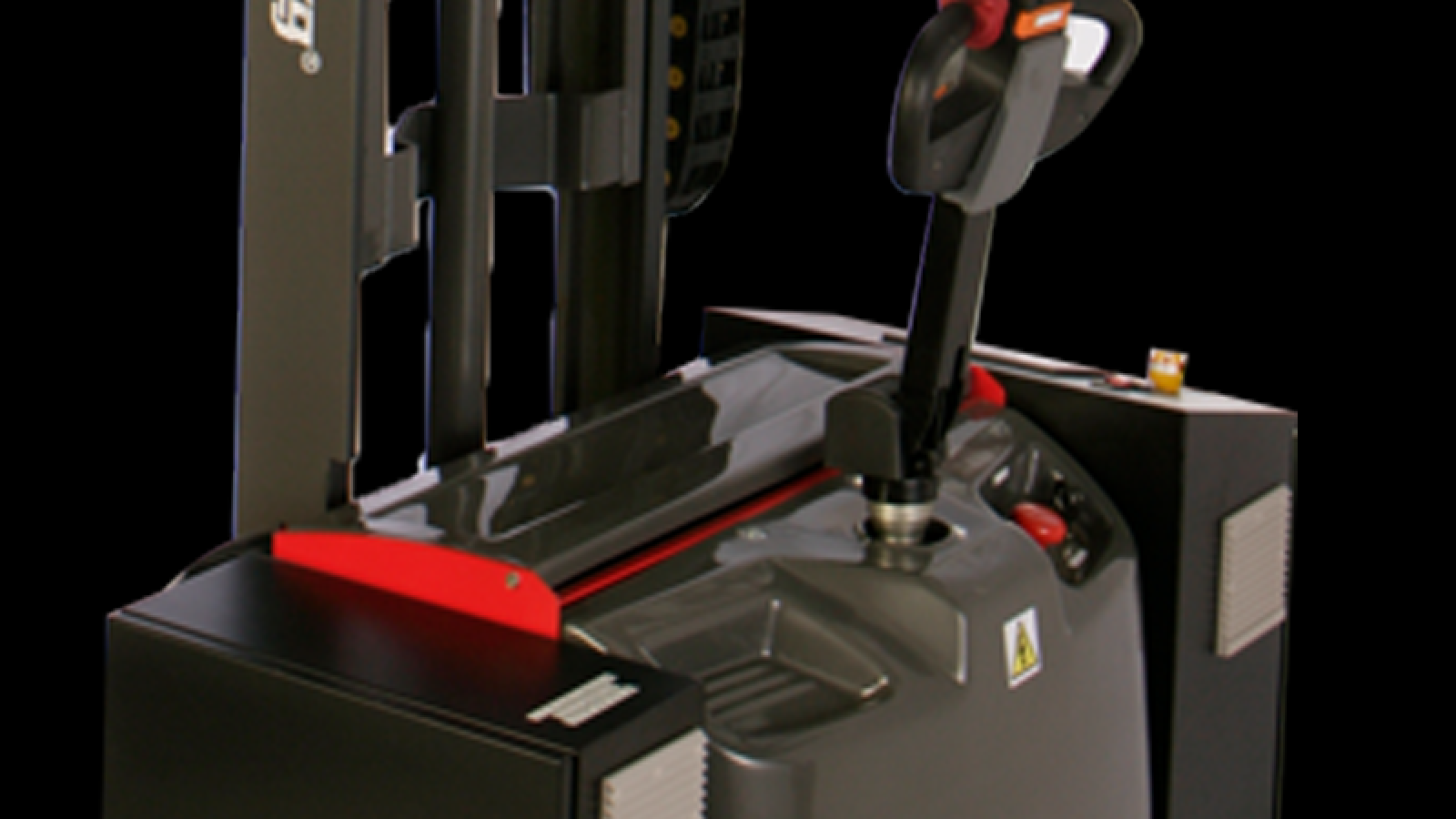

Handling Equipment

Ingot Handling Carts

Crucible Handling Systems

Maintenance

Air Filtration Systems

Maintenance Tools

- Low-power, high-efficiency hotzones that reduce power consumption by nearly half, extend the lifetime of crucibles to approximately 250 hours vs. typical 185 to 195 hours

- Newly-designed heaters and insulation boost efficiency and lower operating costs

- Superconducting magnets vastly reduce power requirements vs. resistive magnets

Growth of a monocrystalline silicon ingot to final semiconductors (chips).

CLICK HERE